Palletizing is the industrial process of grouping cargo onto a pallet to protect the product and prepare it for transportation. The quality of the product after transportation is determined by the quality of palletizing.

"*" indicates required fields

Customized solutions

Products per Day

Units Palletized

Palletizing Lines Completed

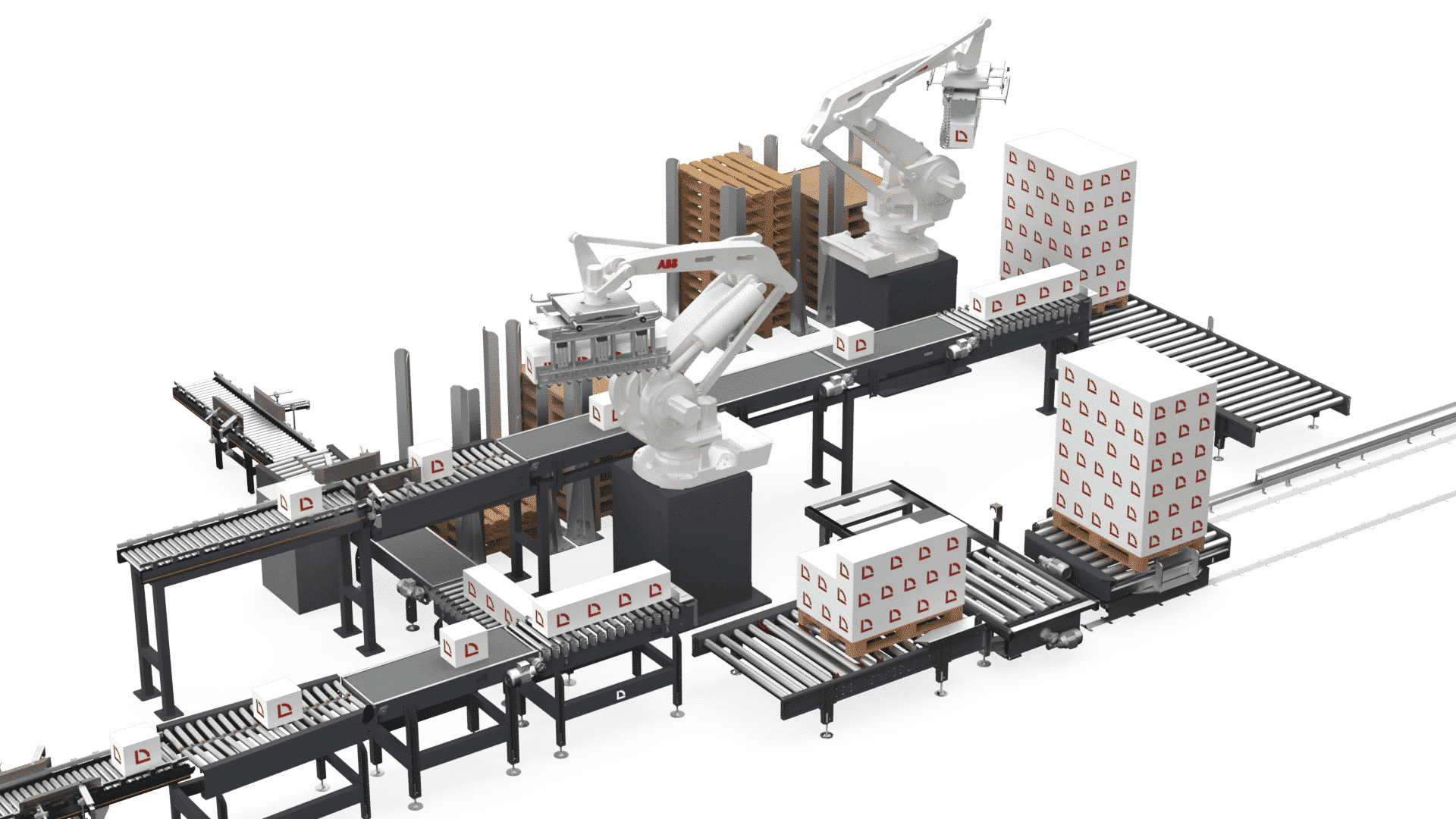

Automatic palletizing: revolutionize your industrial process

Implementing automation, such as automatic palletizing machines, allows for reducing personnel and management costs, controlling and increasing production, and reducing errors.

We serve well-known customers around the world

Benefits of installing a palletizing system

Productivity increase

Palletizers allow for enhanced productivity and control over the end-of-line process. This is due to efficient and established palletizing techniques.

Cost reduction

Automating the end-of-line process helps in reducing personnel costs, freeing them up for more critical areas. Additionally, material loss due to errors or accidents is reduced.

Customized solutions

Brolla tailors all solutions to overcome functionality and stability limitations. Designs are modular and personalized, enabling improvements to the facilities.

Improved palletizing quality

Palletizers ensure high-quality finished pallets, thereby preventing accidents such as cargo detachment.

How does Brolla work?

Ask one of our advisors for information.

Custom concept design and investment estimate

Manufacturing of the palletizing system based on your needs.

Implementation and installation of the turnkey system.

Our palletizers

What products can be palletized?

Brolla has extensive experience designing palletizing lines. These are integrated into many types of industries that have different products. Through cutting-edge and customized technology, these products are palletized efficiently and safely, with the possibility of format changes.

Below are some examples of different palletized products.

Coils

Bales

Cabinet doors

Boxes

Blocks

Ingots

Sheet bags

Paper bags

Real cases

A flour product factory with the capacity to palletize 2 baggers simultaneously, producing 4 million bags per year. Thanks to BROLLA's layer palletizing system and hybrid robot, they can now palletize 4 baggers simultaneously, with a production of 5.3 million bags per year.

Increase in productivity

Cost reduction

Types of bags

Magnesium factory with a capacity to bag 5 million sacks per year, stemming from an outdated palletizing system. Thanks to BROLLA's layer palletizer system, they can now bag 7 million sacks of magnesium annually, with significant improvements in quality, safety, and error reduction.

Increase in productivity

Cost reduction

Error reduction

Pellet factory with a capacity to bag and palletize 4 million sacks per year. With the integration of a BROLLA robotic palletizing line with a bagging system, they can now produce and palletize 6 million sacks per year. Additionally, product losses during bagging, palletizing, and transportation have been reduced by 70%.

Increase in productivity

Cost reduction

Error reduction

FAQs about Palletizing Systems

What should be considered when palletizing?

In automatic palletizing, the types of palletizing are distinguished based on the method used. There are 3 types of palletizers: robotic, layer, and cartesian. Each one has different versions, and at BROLLA, we are experts in all 3 technologies.

What should be considered when palletizing?

Measure the product to be palletized and test palletizing mosaics on the desired pallet size. You can consult specialized palletizing catalogs, such as BROLLA’s, to learn about the most common mosaics.

Fill the pallet surface as much as possible without exceeding it and ensure stability. Always interlock layers to maximize pallet stability.

Should I hire bagging machines for palletizing?

No, bagging and palletizing are separate processes. You can have an automatic palletizer with a manual or semi-automatic bagger; the goal is to have a machine performing the physical part of palletizing instead of an operator. However, when bagging manually or semi-automatically, for good palletizing, all bags should be uniform in size and shape.

Pol Ind. La Borda

C/ Les Borges Blanques 34

08140 Caldes de Montbui

Barcelona, Spain

[email protected]

Tel. 93 566 09 49

From Monday to Friday from 8:00 a.m. to 5:00 p.m