In modern logistics, reducing time in any process significantly impacts warehouse operations, often setting businesses apart from competitors. One of the best methods to increase productivity in a warehouse or distribution center is through automated sorting machines.

If you’re looking to improve the flow of products in your warehouse or logistics center, keep reading to learn how sorters can help.

What is a sorting machine, and how does it work?

A sorter is a goods classification system that automatically categorizes and routes each product to its destination.

By automating this process, the warehouse or distribution center speeds up operations and enhances efficiency, reducing the time spent managing each product and minimizing process-related errors.

What improvements can classification optimization bring?

The goods classification process helps improve internal routes by implementing standardized and efficient paths capable of classifying items at high speeds.

A sorter is characterized by a central goods transport line where parameters and data are measured, such as:

- Volume

- Shape

- Weight

- Color

- Image

- Label type

The collected data is processed in a local database, which communicates with higher-level systems. This data is used to identify and organize goods, redirecting them to different stations based on their destination.

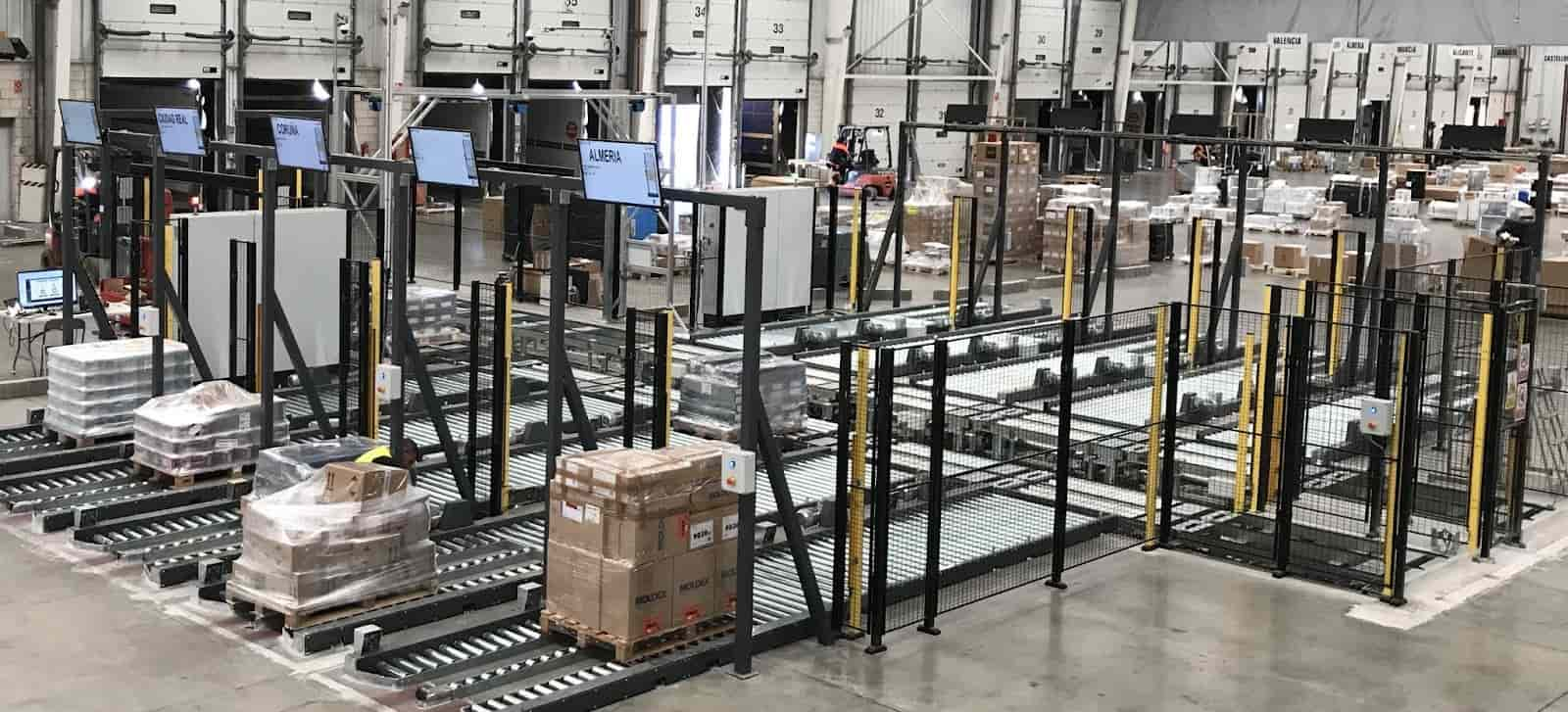

Pallet sorter

Types of Warehouse Sorters

There are no standard types of sorters since they are custom-designed based on specific operational needs. Factors such as activity type, item characteristics, available space, and the number of required destinations influence their configuration, offering nearly unlimited solutions.

The primary classification of warehouse sorters depends on the products they handle. There are unit product sorters, box or container sorters, and pallet sorters like ours.

Additionally, they can be categorized by functionality or morphology, distinguishing between tray sorters, shoe sorters, vertical sorters, and cross-belt sorters.

Benefits of Sorting Machines

Sorters, or classification systems, are primarily automation tools aimed at enhancing warehouse competitiveness.

The main benefits of sorters include:

✔︎ Increased processing capacity: Implementing a sorter in a logistics warehouse boosts productivity by standardizing internal transport routes. This standardization ensures that goods with the same destination always exit at the same point, improving sorting speed.

✔︎ Enhanced internal goods control: Sorters gather extensive data about goods, allowing the creation of a complete profile for each pallet, including detailed information and real-time status tracking.

✔︎ Load verification: The data collected provides additional advantages beyond control. Pallet dimensioning verifies customer load declarations, allowing corrected and accurate invoices. Images of each load enable verification of its condition.

✔︎ Increased revenue: Correcting invoices increases warehouse income, ensuring a quick return on investment.

✔︎ Error reduction: As with all automated processes, errors are minimized. In this case, sorting errors are reduced, leading to fewer returns and decreasing reverse logistics.

Millions of individual items form the flow of goods that travel globally daily and must be delivered on time to the correct destination. This trend requires performance-based logistics with efficient material flow systems.

Pallet sorters are an excellent solution for achieving efficient processes with repetitive internal transport procedures and standardized routes. They also allow load verification, reducing errors, increasing control, and improving profitability through higher revenue.

BROLLA specializes in implementing pallet sorters. If you’re looking to improve your company’s efficiency, this might be a solution worth considering. Contact us if you’d like to integrate this technology.

- What is a Sorting System? - 10 de July de 2025

- Cross-Docking Automation: Mastering Zero Inventory - 28 de March de 2025

- Types of Cross-Docking, Examples, and Which One Is Best for You - 14 de March de 2025