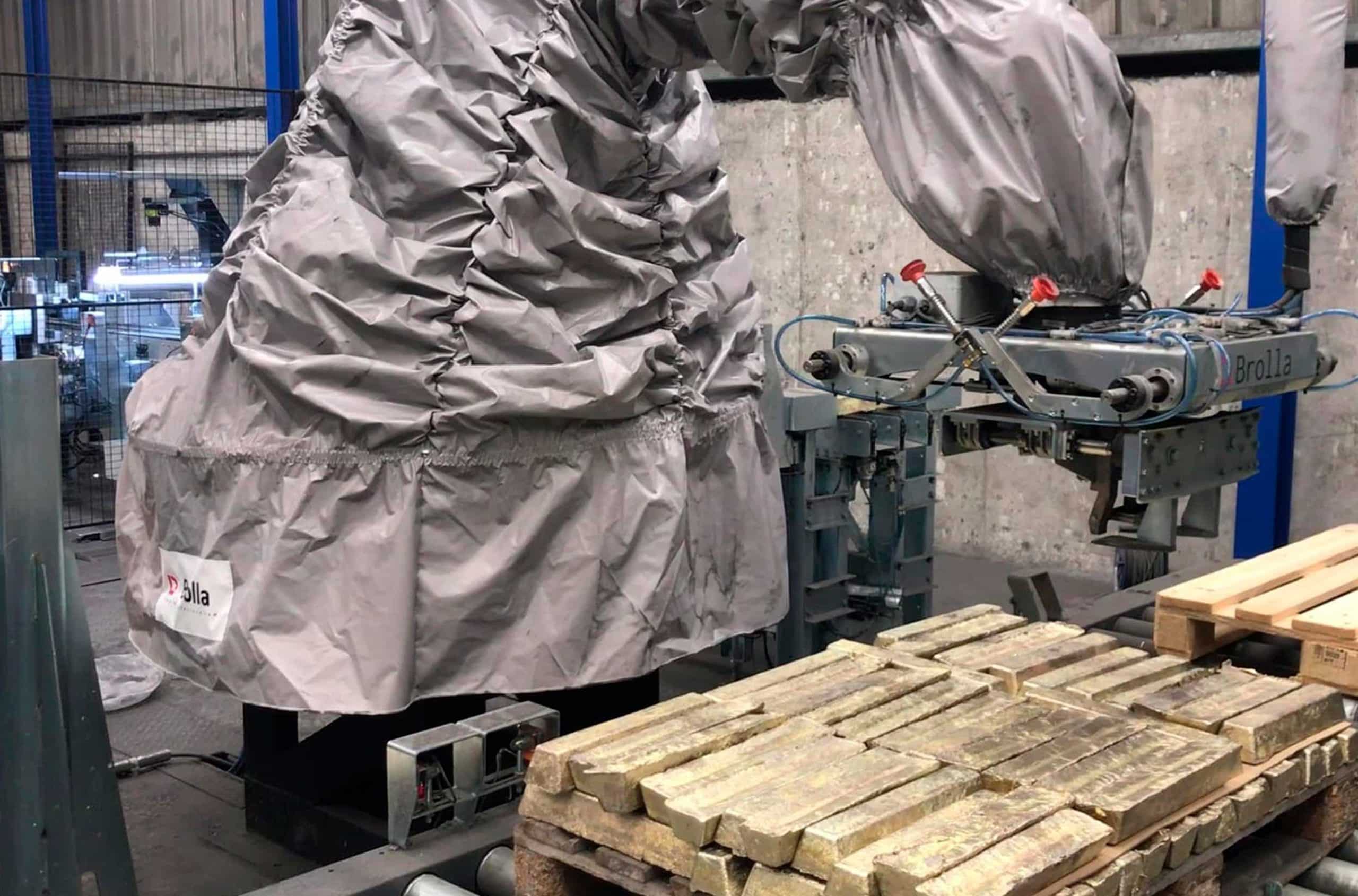

Brolla’s robotic palletizers are a key player in increasing productivity and reducing costs on a production line. The combination of the robot, providing high flexibility, along with Brolla’s know-how in robotic palletizing lines, is the perfect solution for any end-of-line setup.

"*" indicates required fields

Customized solutions

Products palletized per day

Units Palletized

Palletizing Lines Completed

We serve well-known customers around the world

Product Benefits

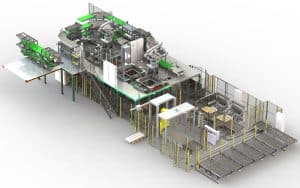

Customized palletizing line

Optimization of movements

Customized end effector

Reduced footprint

High reliability

Characteristics of a robotized palletizing line

The flexibility provided by the robot stems from its ability to adapt to all types of products, spaces, and needs. The final configuration is determined through close collaboration between the customer and Brolla.

- Solution tailored to your products, spaces, and needs.

- Customized end effectors to overcome functionality and stability limitations.

- Capacity to palletize with different entry points, allowing palletizing of more than one line at a time.

Installation Control

Installations with palletizing robots are controlled through a touchscreen that keeps functionalities up to date according to production. This software allows:

- Activation of automatic programs.

- Manual control of all machines comprising the installation.

- Quick creation and editing of palletization recipes.

- Troubleshooting.

How does Brolla work?

Ask one of our advisors for information.

Custom concept design and investment estimate

Manufacturing of the palletizing system based on your needs.

Implementation and installation of the turnkey system.

Real cases

A flour product factory with the capacity to palletize 2 baggers simultaneously, producing 4 million bags per year. Thanks to BROLLA's layer palletizing system and hybrid robot, they can now palletize 4 baggers simultaneously, with a production of 5.3 million bags per year.

Increase in productivity

Cost reduction

Types of bags

Magnesium factory with a capacity to bag 5 million sacks per year, stemming from an outdated palletizing system. Thanks to BROLLA's layer palletizer system, they can now bag 7 million sacks of magnesium annually, with significant improvements in quality, safety, and error reduction.

Increase in productivity

Cost reduction

Error reduction

Pellet factory with a capacity to bag and palletize 4 million sacks per year. With the integration of a BROLLA robotic palletizing line with a bagging system, they can now produce and palletize 6 million sacks per year. Additionally, product losses during bagging, palletizing, and transportation have been reduced by 70%.

Increase in productivity

Cost reduction

Error reduction

Pol Ind. La Borda

C/ Les Borges Blanques 34

08140 Caldes de Montbui

Barcelona, Spain

[email protected]

Tel. 93 566 09 49

From Monday to Friday from 8:00 a.m. to 5:00 p.m