Actualizado el Monday, 27 January, 2025

To maximize the productivity of a logistics center, carriers must collect the necessary data to apply accurate pricing to shipments. Achieving this requires optimizing and classifying the loads.

What Does an Automated Pallet Dimensioning System Do?

Automated pallet weighing, measurement and control systems gather data such as volume, weight, identification images, and barcode scanning. This is achieved through weighing, volumetric, and photographic control of pallets using sensors and weighing instruments.

These pallet dimensioning systems can operate independently or integrate into larger systems, such as pallet sorters or inbound inspection stations in warehouses. Brolla specializes in implementing these systems.

Advantages of Implementing a Pallet Dimensioning System

Implementing such a system in a warehouse or logistics center offers numerous advantages:

- This system streamlines the data collection process as opposed to manual data collection. Measuring volume, weight, and taking photographs is done in seconds. Manual measurement can be very slow and difficult.

- Due to the simplicity of the machines, this type of system requires very little maintenance and has a very long lifespan. This minimizes downtime and maximizes the machine’s amortization time.

- By collecting all this data, many benefits are achieved. In cross-docking warehouses, incorrectly declared loads can be detected, ensuring a quick return on investment. In warehouses or logistics centers, greater control and knowledge of loads are achieved thanks to the association of multiple data points with them.

- Measurement accuracy is maximized. The volumetric system operates using infrared laser detection devices, and the weighing system uses scales. The high precision of the system allows the weighing system to be certified. There is no regulated certification for volume measurement, so this measure cannot be certified.

- Pallet scanning systems, in addition to collecting and storing data, help improve warehouse management. Thanks to pallet identification, the system displays the destination of the pallets, allowing them to be taken directly to their corresponding location as soon as they exit the system. This can be done automatically through sorters or automated warehouses, or manually in more compact systems.

How a Pallet Scanning System Works

The operation of these facilities is very simple and efficient. Using minimal space, the collection of the data on the goods is carried on quickly with high precision.

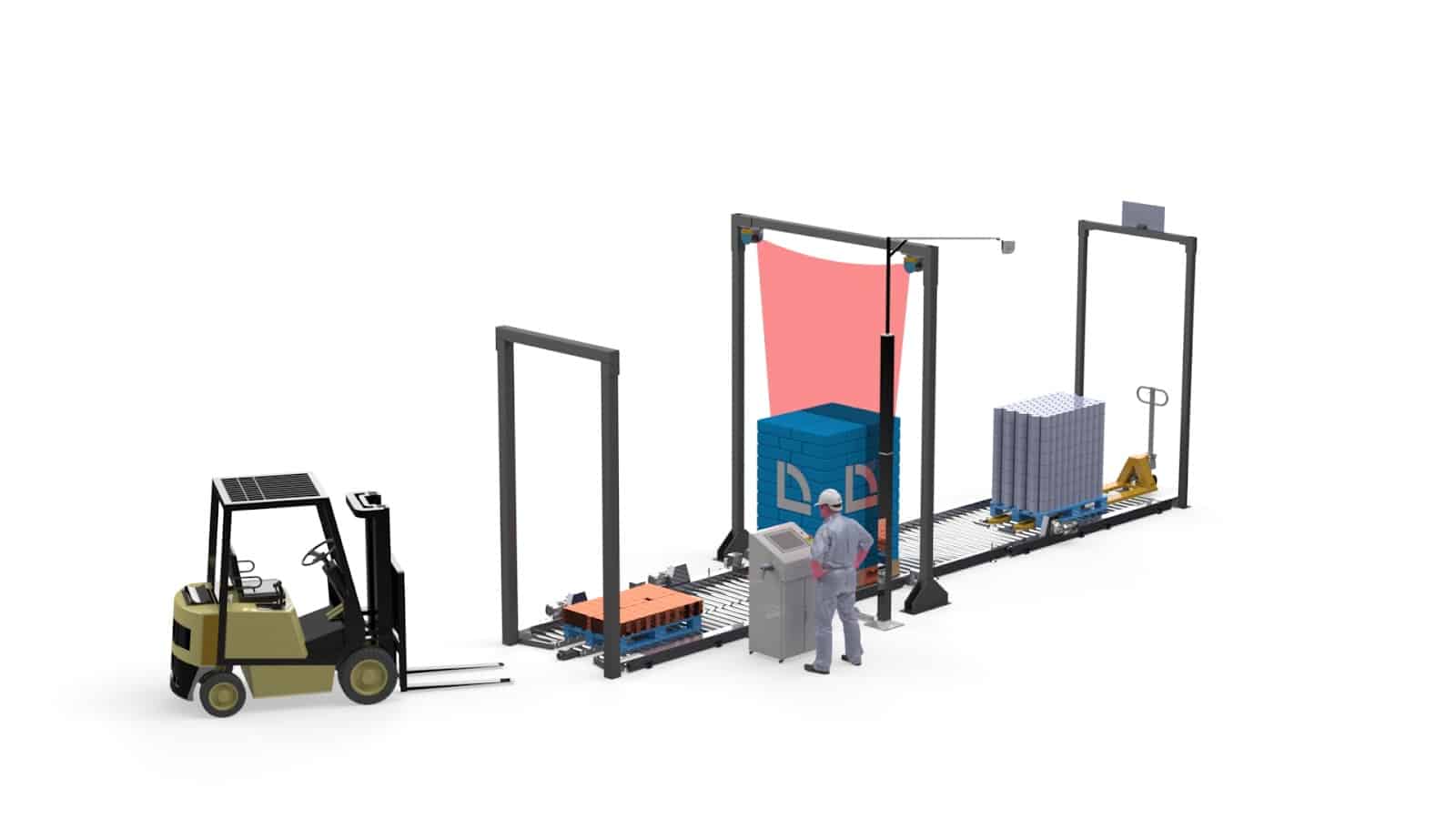

The automated pallet dimensioning systems mainly consist of a conveyor line, where various data sets are collected as the pallet advances along the line.

To fulfill all the functions specified in this article, these volumetric measurement and control systems include the following machines:

- Entry/exit machines: This type of conveyor facilitates the placement of pallets in the system, either with a pallet jack or forklift. This is done through a roller conveyor adapted to the forks of these vehicles.

- Weighing system: This system integrates with a roller conveyor using scales and various devices to collect and transfer data from the scales. This system can be certified.

- Scanning system: The volumetric measurement system is installed at a point along the line, placed in a structural arch. It incorporates devices that dynamically measure volume.

- Photographic system: To take an image, a camera is integrated to capture a photo identifying the pallet passing through the system.

Applications of Dynamic Pallet Dimensioning Systems

The automated volumetric measurement and control systems described can be used in many areas of the supply chain. Primarily, they are integrated into logistics operations, where the data collected by these systems is most valuable.

The transportation hubs can apply precise prices to shipments thanks to accurate pallet measurements. This allows for the correction of invoices and, therefore, obtaining more operational benefits. In addition, it helps organize transport with precise measurements of the volume and weight of all loads that will occupy a truck.

In warehouses and distribution centers, it is possible to optimize and ensure the storage of products thanks to the measurement equipment. It ensures the consistency and integrity of the load, avoiding possible accidents. This minimizes opportunity costs and the dangers that accidents may cause. Pallet measurement and control systems are usually integrated as inbound inspection stations at the entrances of automated warehouses.

Shipping centers can know shipping rates in advance, thanks to accurate measurement, and record images of the load’s condition. This minimizes reverse logistics.

Brolla Factory’s Pallet Dimensioning Systems

As a specialist in pallet dimensioning, Brolla has designed an all-in-one system, the CN.1000.

The CN.1000 system is an installation that combines weighing, volumetric, and photographic systems. Weight and volume measurements allow for the benefit of correcting invoices. The collected data can be integrated into larger IT systems.

It can be configured with different conveyor technologies, such as roller or chain conveyors, depending on the application.

Technical Specifications

Real example of implementing a Pallet measurement and control system

A cross-docking center with an operational capacity of 1,000 pallets per day lacked the time to manually weigh and measure the pallets, making it impossible to verify the weight and volume declarations made by customers.

Thanks to a pallet measurement and control system, the CN.1000 model, the center increased its operational capacity to 1,500 pallets per day. This was achieved through standardized internal transport procedures and routes, as well as recovering an average of €8 per pallet.

Automated pallet dimensioning systems enable logistics companies in many sectors to carry out precise and rapid load measurements. They also facilitate measurement, as they can measure regular and irregular loads of any shape. These benefits aim to improve efficiency and maximize revenues, making the implementation of a pallet measurement system a solution worth considering.

If you want to integrate this technology, Brolla specializes in it, with references from highly reputable clients worldwide. Don’t hesitate to contact us.

- What is a Sorting System? - 10 de July de 2025

- Cross-Docking Automation: Mastering Zero Inventory - 28 de March de 2025

- Types of Cross-Docking, Examples, and Which One Is Best for You - 14 de March de 2025