Actualizado el Monday, 27 January, 2025

What is Palletizing?

Palletization is a logistics technique that involves grouping products on a pallet to streamline storage, transportation, and handling processes. Additionally, it serves to protect the goods.

The key to palletization lies in the use of pallets as a single base platform for various unit loads. This simplifies the handling of goods, as the load can be moved all at once instead of moving each product individually.

Advantages of Palletization

Palletization offers various benefits in the logistics field, including space optimization in warehouses and containers, reduced logistics costs, improved handling, distribution, and product selection, as well as damage prevention during transportation.

Here’s a closer look at each advantage:

➡️ Optimization of Space in Warehouses and Containers

Palletization maximizes the use of available space in warehouses and containers. By using pallets as a base, goods can be stacked in an orderly and stable manner, helping to optimize vertical space effectively.

➡️ Reduction of Logistics Costs

Palletizing goods significantly reduces logistics costs. Efficient storage in warehouses and containers minimizes the need for physical space, leading to lower rental costs or the ability to store more goods in the same area. Besides that, pallets facilitate the loading and unloading of products, speeding up processes and reducing handling times, which lowers labor costs.

➡️ Improved Handling, Distribution, and Product Selection

Palletization greatly enhances the handling, distribution, and selection of goods. Standardized unit loads make it easier to move and transport pallets with forklifts, streamlining logistical processes. This also simplifies locating and accessing the required products, reducing search time and increasing efficiency within the supply chain.

➡️ Prevention of Damage During Transportation

Palletizing goods helps prevent damage to goods during transportation. Properly organizing and securing items on pallets with suitable fastening techniques and materials ensures that the load remains stable and undamaged during handling and transit.

Tipos de paletización

Los principales tipos de paletización son la paletización manual, la paletización semiautomática y la paletización automática, se clasifican según el grado de automatización del proceso.

A medida que se añade más automatismos a la paletización, se obtienen mejoras en eficiencia, reducción de costes y optimización del espacio. A continuación, explicamos cada una de ellas.

Types of palletization

The main types of palletization are manual palletization, semi-automated palletization, and automated palletization, classified based on the degree of automation in the palletizing.

As more automation is introduced, efficiency, cost reduction, and space optimization improve. Here’s a breakdown of each type:

Manual Palletization

Manual palletization relies entirely on human effort. Workers pick up unit loads and place them individually on the pallet.

The main advantage is that it requires minimal infrastructure or investment.

On the contrary, manual palletization is highly repetitive and physically demanding for workers, as the products involved are often heavy. This can negatively impact the occupational health of the operators. Additionally, it is a slow and time-consuming process, leading to low productivity.

This type of palletization is suitable for low production and storage volumes where the loads are not heavy.

Semi-automated Palletization

Semi-automated palletization introduces automation to some subprocesses compared to manual palletization but not to the entire process.

There is no specific task that must be automated for semi-automated palletizing to take place. For example, automation can be applied to the placement of unit products or the wrapping of pallets, among other tasks.

Adding automation improves productivity and occupational health compared to manual palletization, as it reduces the workload on operators. However, it does not completely eliminate human involvement, which can still lead to injuries, errors, or inefficiencies.

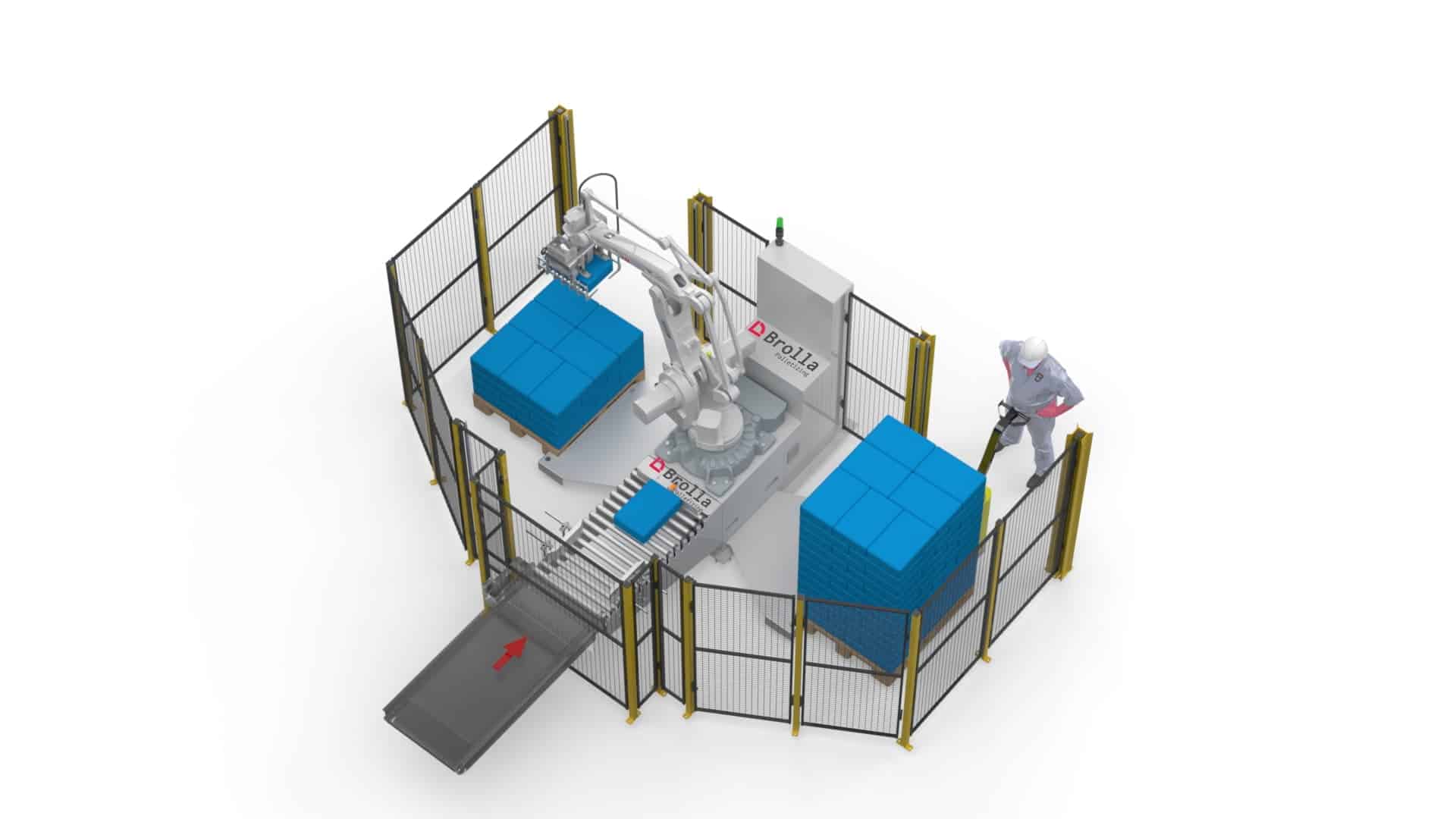

An example is compact palletizers, which automate the product placement process but still require human intervention for loading and unloading pallets or wrapping them.

Another example could involve manually placing unit products and automating the pallet wrapping process using semi-automatic wrappers.

This type of palletization does not require a significant investment and typically involves compact machinery. It is ideal for medium to high production activities where large investments or space for larger-scale solutions are not feasible.

Automated Palletization

Automated palletization is the variant that requires the least human intervention in repetitive and heavy processes. It automates the placement of unit products onto pallets, pallet feeding, pallet wrapping, and final load extraction.

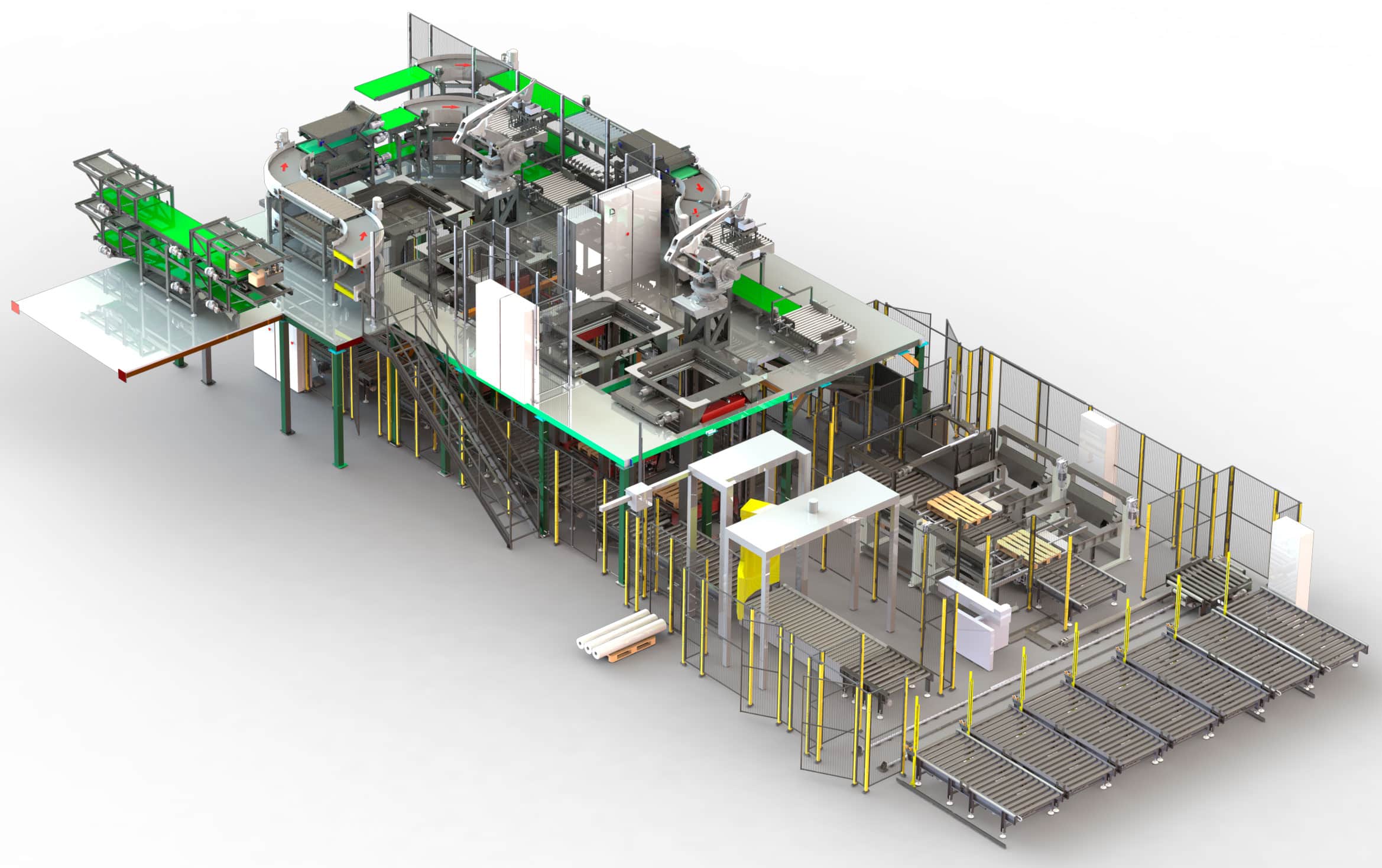

This type of palletization is achieved through automated palletizing lines, which consist of one or more palletizers, pallet dispensers, pallet conveyor lines, automatic wrappers, and more. Machines can be added or removed to adapt to different situations and requirements.

Automated palletizing allows for benefits in many different areas, such as productivity, reduction of operating costs, improvement in pallet quality, better load securing; among others.

Automated palletizing lines require a greater investment and space than other types of palletization.

These solutions are perfect for various types of industries such as food, agriculture, electronics, storage, retail, or pharmaceuticals. They allow handling large productions and loads, making them a universal solution.

Summary of Palletization types and their characteristics

| TYPE OF PALLETIZATION | IDEAL USE | ADVANTAGES | DISADVANTAGES |

| Manual Palletization | Low production and storage volumes, non-heavy loads. |

|

|

| Semi-Automated Palletization | Medium to high production activities with limited investment or space. |

|

|

| Automated Palletization | Food, agricultural, electronics, storage, retail, and pharmaceutical industries. |

|

|

Palletizers you can find

Within palletization, there are different types of palletizers and palletizing robots. Here are some of them:

Robotic Palletizing Lines

Robotic palletization is exactly that—using robots to facilitate the palletization process. This automates the workflow, as robots become an integrated component in palletization applications. It provides a high level of dynamics, as well as flexibility and functional reliability.

Layer Palletizers

The layer palletizing systems are fully automated and allow for fast and efficient stacking of products. It includes various components to organize, orient, and form layers. With the use of a layer compactor, the stability of the stack is ensured.

Cartesian Palletizers

Cartesian palletizers are particularly recommended for end-of-line applications with low or medium production volumes. This is because they offer simple solutions that are adaptable to limited spaces.

How Do I Know if Palletization Can Be Applied to My Activity?

Palletization can be adapted to the needs of any company thanks to the different types of palletization available, offering a wide range of solutions.

For small-scale production, manual palletization can be tailored to your needs. However, as production increases, the capacity for palletization must grow, which leads to the need for automation to achieve the desired results.

Brolla Factory specializes in integrating all types of semi-automatic and automatic palletizing lines, providing various solutions to suit all kinds of products, productions, and spaces.

If you want to improve efficiency, reduce costs, and optimize warehouse space, palletization is the answer.

- What is a Sorting System? - 10 de July de 2025

- Cross-Docking Automation: Mastering Zero Inventory - 28 de March de 2025

- Types of Cross-Docking, Examples, and Which One Is Best for You - 14 de March de 2025