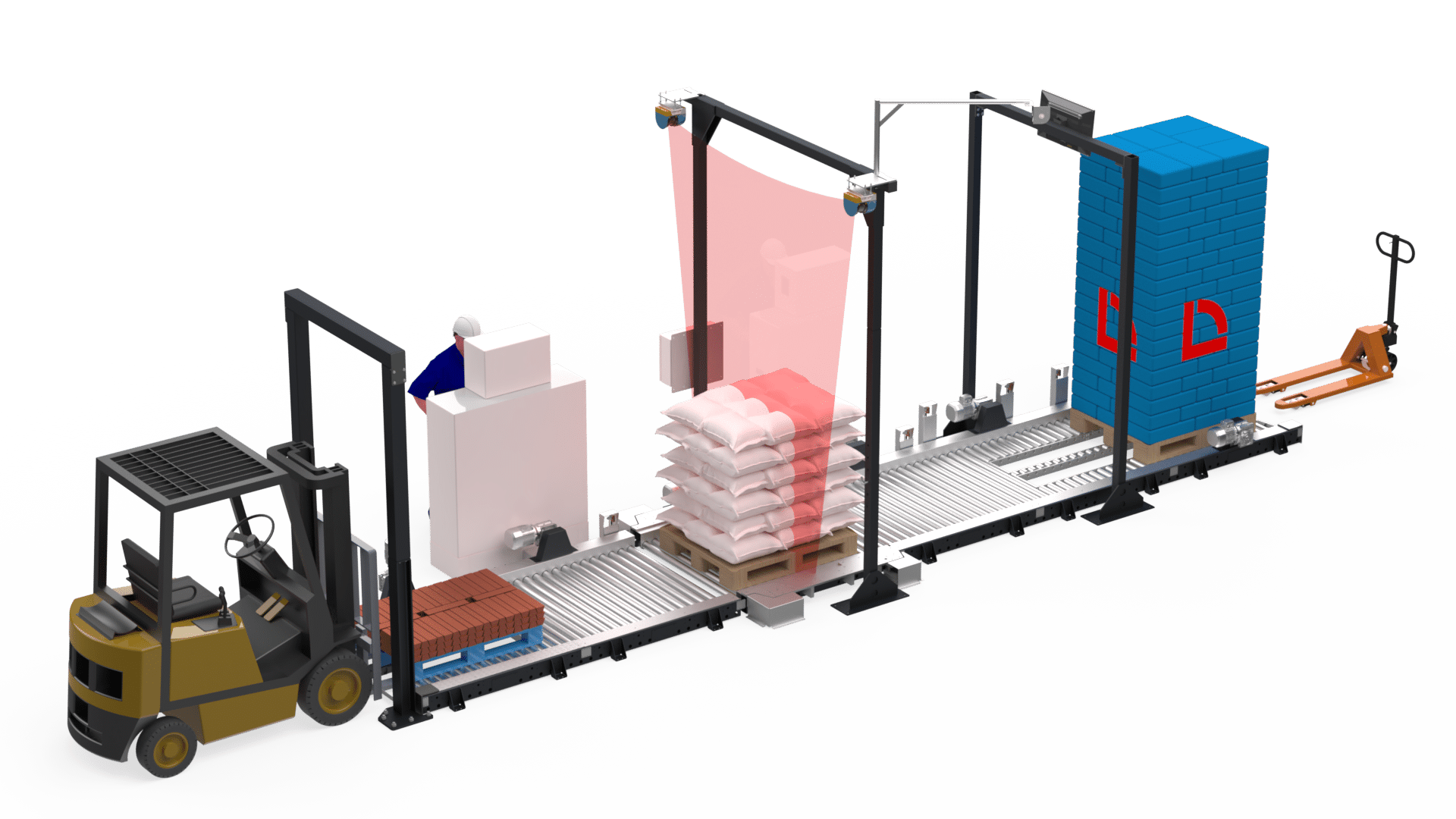

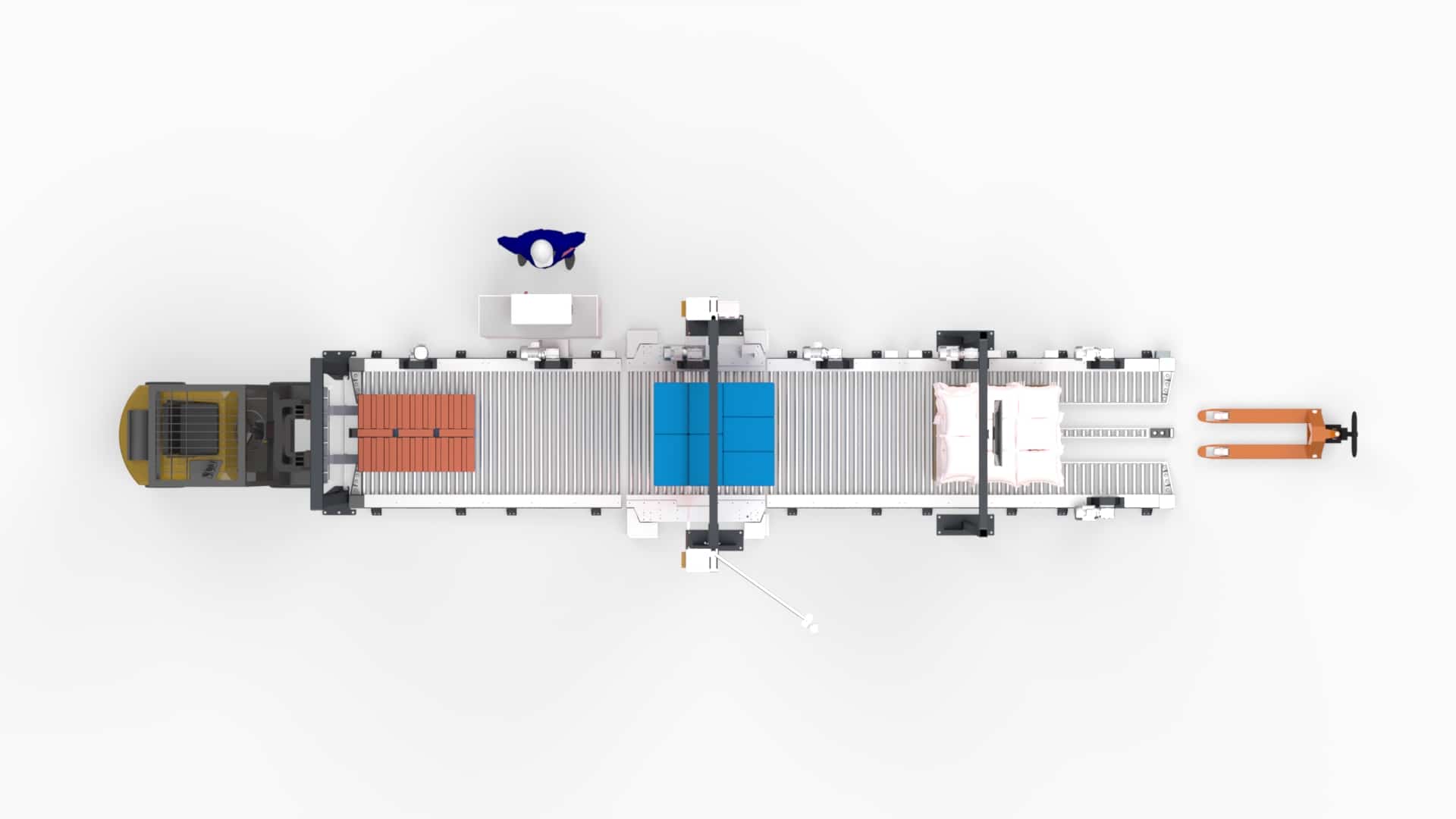

The simplified and compact design allows you to reap the benefits of controlling the volume and weight of a pallet with minimal investment. Additionally, warehouses with Brolla machines have managed to increase the number of daily pallets handled with the same human resources, thanks to the separation of the loading and unloading traffic.

"*" indicates required fields

We serve well-known customers around the world

Product Benefits

Compact and versatile system

Measures regular and irregular objects

Accepts objects of large volume and weight

Maximum precision in measurement

Simple maintenance

Technical specifications

- Measuring Capability: Regular or Irregular non-transparent objects

- Minimum Object Dimension: 200x200x200 mm

- Maximum Object Dimension: 2.000×1.350×3.000 mm (may be adapted to customers needs)

- Measurement Accuracy: +/- 20mm

- Maximum Weight of Load: 1.500 kg

- Bar Code reading: Any type, 1D or 2D

- Integration Interface: Web Service (Ethernet), or Excel (XML), File Output via RS232.

- Data Output: Max. Width, Max. Length, Max. Height, Weight, Barcode, Image, Date

- Operating Voltage/Current: 380V/ 30A (max.)

How does Brolla work?

Ask one of our advisors for information.

Custom concept design and investment estimate

Manufacturing of the palletizing system based on your needs.

Implementation and installation of the turnkey system.

Real cases

At a Cross-Docking center handling around 1,000 pallets per day, none of these pallets were previously checked for weight and volume declared by the end customer. With the implementation of a BROLLA Pallet Sorter, they are now verifying the weight and volume of each pallet. Additionally, they have improved operational capacity to 1,300 pallets per day, thanks to enhanced internal transport routes and repetition of paths.

Increase in productivity

Dimension and weight control

Return on investment

A logistics center near Barcelona has an operational capacity of up to 3,000 pallets per day, of which only a few are manually checked for volume and weight. With the implementation of two BROLLA Pallet Sorters, they process over 4,000 pallets daily. Additionally, they have been able to incorporate automated weight and volume control of goods into their warehouse, allowing for corrections to be made to shipping guides.

Increase in productivity

Dimension and weight control

Return on investment

Pol Ind. La Borda

C/ Les Borges Blanques 34

08140 Caldes de Montbui

Barcelona, Spain

[email protected]

Tel. 93 566 09 49

From Monday to Friday from 8:00 a.m. to 5:00 p.m